Why Pipe That Meets the API Standards Stands Above the Rest

There’s no room for substandard equipment in the oil and gas industry. The quality of just one pipe could be the difference between success and disaster for an operation and its crew, the environment, the company’s bottom line, and its reputation.

For high-performance drilling operations, companies and engineers turn to pipe that meet the standards of the American Petroleum Institute (API). The organization has established rigorous criteria that challenge manufacturers to meet the industry’s toughest specifications for safety, reliability, and efficiency. Zekelman Industries has not only met these ambitious benchmarks, but it has consistently exceeded them for years.

Obtaining API certification is no easy task. Every part of the manufacturing process is rigorously examined and tested: chemical and physical properties of raw materials; design specifications for pipe wall thickness, diameter, and pressure strength; manufacturing processes including welding, forming, and heat-treating standards; and, ultimately, in-the-field performance metrics. Extensive testing, documentation, and auditing throughout the licensing process verify that a facility consistently produces pipes that meet API’s high quality and reliability standards.

Setting the Highest Bar

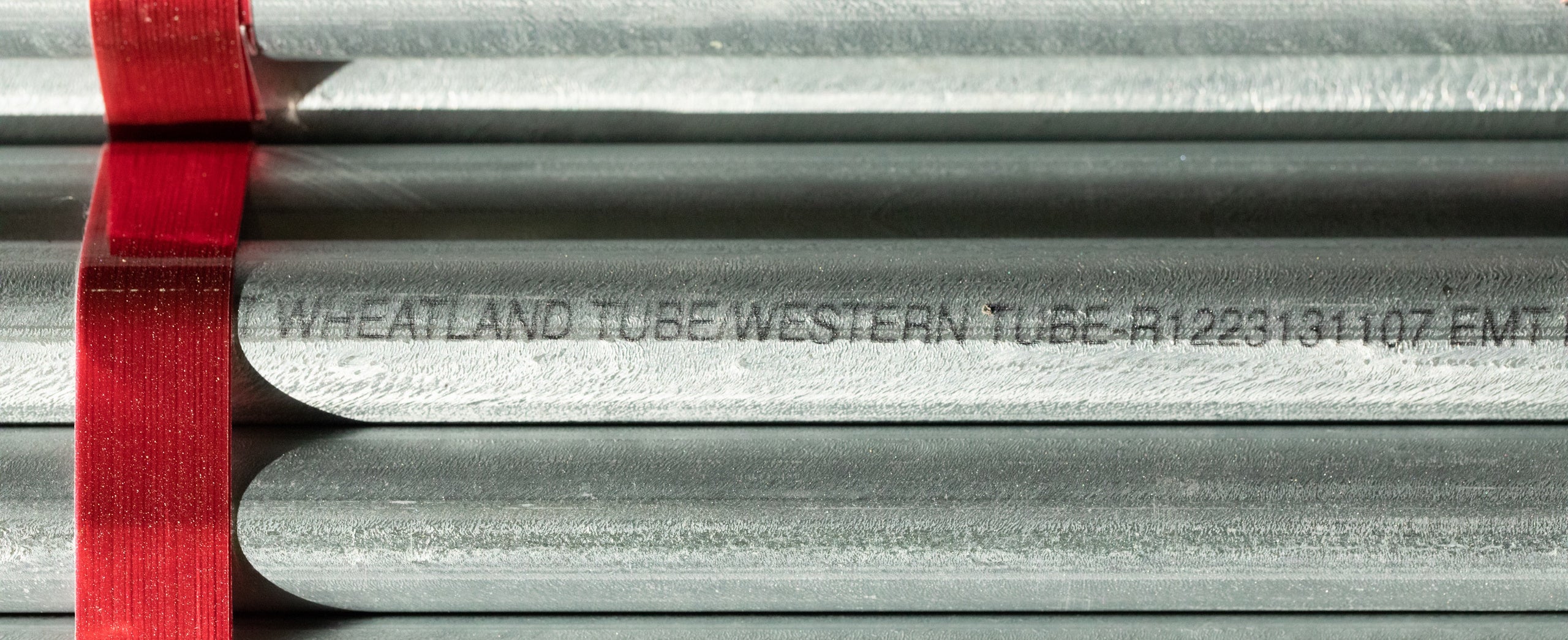

Zekelman’s Wheatland Tube has made significant financial and resource investments to meet the API’s stringent requirements at its Wheatland, Pennsylvania, and Warren, Ohio, facilities. As Greg Maurer, Director, Technical Services and QA at Wheatland Tube, explains, “Our quality system and our standards have to be set to meet the API Q1 standards. And that doesn’t go away — the quality system is the quality system, so it’s set. All of our procurement practices and all of our operating practices must meet those requirements every day.”

Part of what elevates Wheatland Tube’s pipe products above competitors is the fact that all products produced at these certified locations are produced with the same level of quality control to meet API requirements. “That’s not really anything our standard pipe or sprinkler pipe competitors are implementing or doing,” explains Jesse Comber, Western Regional Sales Manager at Wheatland Tube.

Other quality specifications, such as ASTM, set specifications, but without third-party governance — making compliance self-managed.

“All manufacturers self-certify to an ASTM specification,” says David Hoffman, Central/Northeast Regional Sales Manager at Wheatland Tube. “That essentially means that you’re testifying when you stencil that product that you’re meeting that specification.”

ASTM specifications don’t include independent quality checks however, API specifications require consistent external monitoring to ensure adherence to its high standards.

“API is stringent, and there is, for lack of a better term, a police force,” says Hoffman. “They will come in, and they will pull your product out of the marketplace if it’s not compliant. ASTM, although [it has] great standards — there’s nobody standing behind it. The API does, and that’s why we have to be so technically accurate when we manufacture our product.”

A Push for Excellence

Meeting the API standards requires an audit of a facility’s quality system, capabilities, and product compliance. Audits typically take three to five days to complete.

Once a facility is deemed API-compliant, the work doesn’t end there. Audits must be repeated every three years to confirm that product standards are continually met. “We are allowed to put the API Monogram on our product — and they take that very seriously,” Maurer says.

The API standards are constantly being updated to ensure all areas of oil and gas operations, from offshore rigs to onshore wells and processing facilities, are working safely and efficiently with the latest technical and environmental innovations.

There’s nothing better than building something you believe in.

Zekelman companies are in constant motion, expanding our teams and challenging convention.

"*" indicates required fields