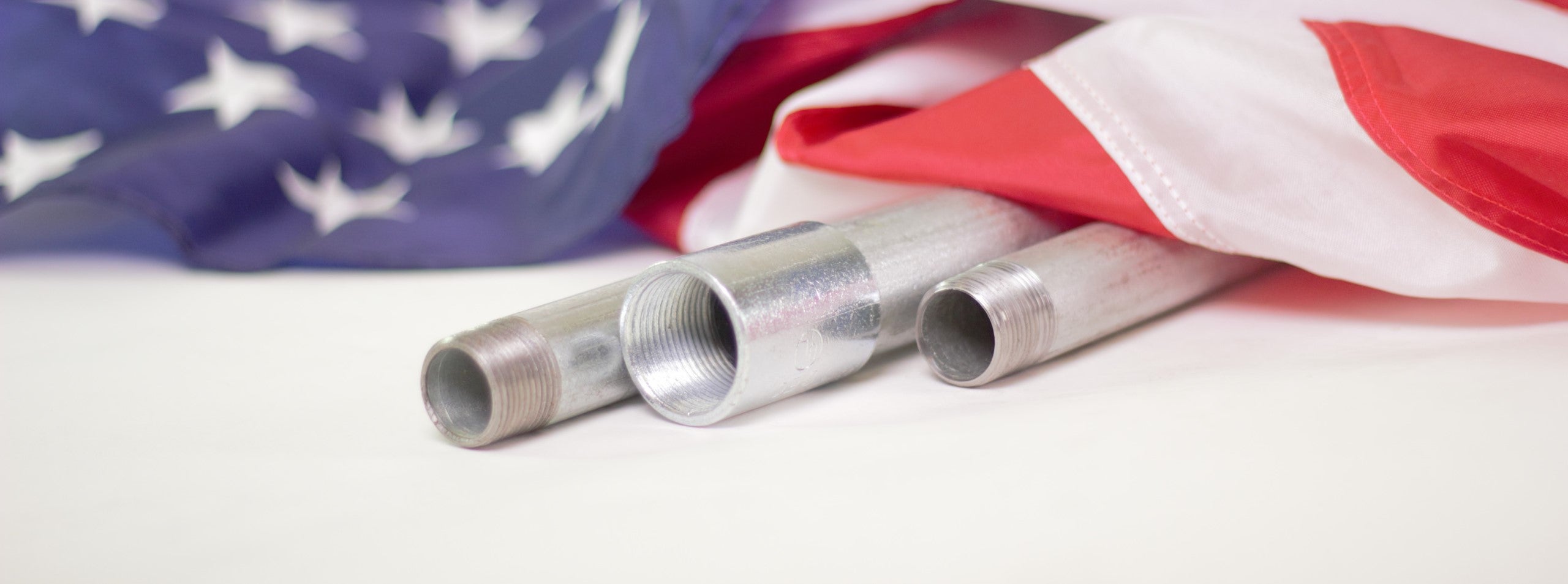

The Case for American-Made Steel Conduit

Electrical contractors and distributors are often under pressure to keep costs down, which can make the low price of imported conduit appealing—until you factor in the true cost.

Using inconsistent or inferior quality conduit can lead to project failures as well as safety hazards, posing a risk to your business—and your customers.

That’s why we sat down with Tom Reed, Contractor Technical Product Specialist at Zekelman, to discuss the critical differences in imports versus domestic conduit quality, and shed light on some of the risks of using imported conduit.

Q: What differences have you noticed in the quality of domestic versus imported conduit?

A: I’ve talked to a lot of contractors about it, and the appearance of imported conduit is fine on the outside. You don’t know it’s going to perform poorly.

The trouble comes after the fact—when workers start bending imported conduit or start trying to thread it. When they’re actually putting it through normal wear and tear on a job site.

The inside coating of Zekelman’s U.S.-made conduit is smooth, making it easier to pull wires through. Wires are expensive—especially larger feeder or medium voltage cables—so if the inside of the conduit is rough, not only is it harder to pull the wire through, but you could also damage the wire. And if you mess up the wire, you can’t just fix it. You have to pull it out, buy new wire, and start over.

The issue is you can’t always see these problems right away. A 10- or 20-foot piece of conduit may look fine on the outside, but the inside is where most issues occur. The only way you know there’s a problem is when it creates another problem, and by then, you’re already dealing with expensive fixes.

Q: How aware are electrical contractors and distributors of these quality differences?

A: I don’t think they’re aware of the differences. Out in the field, purchasing agents have their job, and their job is to save the company money. When they’re buying the cheapest price conduit out there, it’s probably not domestic.

Imported products are pretty good at disguising that they’re manufactured offshore, and the guys out in the field don’t always recognize that. It’s often an assumption that everything’s made here in the U.S.

Q: What types of imported conduit should distributors and contractors avoid, and why?

A: It’s often made from Chinese-made steel, whether it comes from Mexico, Korea, or Vietnam. There are a couple of things, as Americans, I think we should pay attention to. Number one, if you’re buying domestic, you’re supporting American labor. You’re supporting American products. You’re supporting companies that pay taxes in your community. You have to be aware of that.

These importing companies don’t care. They’re not here. They’re hiring cheap labor, making a poor-quality product, and have a cheap price. They’re just trying to sell volume.

If you’re an electrical contractor or electrician, that’s your job. That’s your livelihood. It’s a skill, and they take pride in that skill, so that’s their stamp. When an artist signs a painting, that’s basically what they’re doing. They don’t want to have their name on anything that is of poor quality. Contractors don’t want to get called back to a job, and their customer says, ‘Hey, this looks terrible.’ They could lose business in the future. So we need to make them aware of the risks of imported conduit before that happens to them.

Q: What are the risks of using unregulated conduit in construction projects?

A: If you have imported conduit and you put it in a new building, maybe it won’t rust tomorrow. Maybe it will rust a month from now. Maybe it will rust a year from now. But when it does, that’s a problem.

If that conduit fails when you’re two or five years down the road, that’s going to be a problem. It could be a fire hazard. It could fall apart and fall on somebody’s head. It doesn’t happen every day, but there’s no doubt it can happen.

Q: Cost is always a factor in projects. What would you say to contractors who are worried about paying more for domestic conduit products?

A: At Zekelman, we often say that cheap is expensive. While imported conduit might come at a lower cost, domestic conduit is going to perform better over time and save you money in the long run.

I grew up on a farm, and my dad told me, ‘Do it right the first time, so you don’t have to do it twice.’ If you use a poor-quality product, you’ll probably have to go back and replace it.

So do it right the first time: buy American-made products, and know you’ll walk away with the peace of mind that it’s made to last.

Q: How does Zekelman ensure its electrical conduit meets the highest industry standards?

A: First of all, we follow UL standards. These are safety guidelines developed by Underwriters Laboratories to ensure that conduit meets strict safety, performance, and quality requirements. They protect contractors by reducing the risk of electric shock, fires, and other hazards.

We’re also a privately held company. When we sell products, our reputation is on the line too. We stand by our products.

If you’re buying it from Zekelman, and you have an issue, or question, or need something, you can reach out and call our reps. You can call our distributors. You can call me. You can call any of our teams, and we’ll take care of it.

If you’re buying something from China or Mexico, who are you going to call? There is no support. It’s just a cheap price, and they walk away. We’re not like that. We’ll have an answer for you.

Join the movement to demand domestic. Learn how you can make a difference by supporting American-made steel products at zekelman.com/demand-domestic.

There’s nothing better than building something you believe in.

Zekelman companies are in constant motion, expanding our teams and challenging convention.

"*" indicates required fields