5 Lesser-Known Reasons to Demand Domestic Conduit

Buying American-made electrical conduit is a smart decision for a few obvious reasons. Its exceptional quality and reliability are several top-of-mind differentiators. So is the fact that buying domestic products supports stable jobs for American workers—growing our economy and building strong U.S. communities.

But there’s more to the story.

The benefits of choosing U.S.-made over imported conduit extend far beyond what electrical contractors and distributors may initially consider. And these lesser-known reasons only strengthen the case for demanding domestic products for your projects. Let’s take a look.

1. Supply Chain Stability

During the pandemic, businesses discovered a new vulnerability: the extent to which their operations could be idled by imported goods either stuck in customs or slowly making their way across the world.

The COVID era may now be in the rear view, but the threat of supply chain disruptions remains. Electrical conduit manufactured in a different hemisphere—or even just across the border in Mexico—not only takes much longer to ship, but it’s also more vulnerable to prospective delays, explains Tom Reed, National Technical Sales Manager at Zekelman Industries. From severe weather and customs complications to the complexities of multimodal international transport, countless challenges can disrupt and delay projects in an international supply chain.

“It’s a lot quicker and more predictable to put an order of conduit on a semi in Rochelle, Illinois, and get it to, say, Oklahoma—compared to throwing it on a ship in China,” Reed says. “It gives you peace of mind to know that your conduit isn’t sitting in a harbor somewhere waiting to get unloaded.”

For companies with large teams standing by at a job site, a couple of days spent waiting for conduit can translate to an enormous financial cost—not to mention the uncertainty around when exactly the shipment might finally arrive. By choosing American-made conduit, contractors can count on having the quality of the material they need available when they need it.

2. Coast-to-Coast Support

What if something does go wrong—whether it’s an availability issue or you have a concern about a product’s performance? With an international manufacturer, you could be left scouring the internet for spec sheets or leaving messages that won’t be returned until the next day—if ever. Even if you’re able to speak with a knowledgeable, helpful human, it’s probably too expensive and impractical for that vendor to send someone to the work site to help quickly resolve the issue.

With an American manufacturer, however, you can expect responsive support. For example, customers can quickly reach out to Zekelman if they run into issues, and they can do it with the confidence that a dedicated team member will be available to help, Reed says.

And if more is required, Zekelman shows up—even if that means hopping on a flight.

“If there’s a quality issue out in the field, I get on a plane from my base in Indianapolis, and I fly to that job site—I don’t care where in the country it is,” Reed says. “We address the problem in person to make sure that the customer is taken care of.”

3. A Sustainability Edge

American-made conduit provides several notable sustainability advantages compared to imported products. First, U.S. manufacturing facilities are held to especially stringent and well-enforced environmental standards compared to peers around the world. Zekelman, for example, has water-treatment facilities embedded within its factories so that nearby waterways aren’t polluted.

Additionally, U.S. factories such as Zekelman’s use extensive on-site material collection and recycling processes to ensure that byproducts from the conduit manufacturing process aren’t disposed of in ways that are harmful to the environment.

Not only is domestic conduit required to meet high standards for sustainability, but so are the underlying materials: U.S.-made conduit is produced using U.S.-made steel, which is subject to similarly high manufacturing standards.

“We’re very mindful of it,” Reed says. “Everything we can recycle, we recycle.”

Then there’s transportation: It’s no surprise that closer is greener. Using conduit manufactured near your job site is simply more sustainable than imports that may travel thousands of miles—or halfway around the world—and create a much larger environmental footprint.

The payoff is so high, Reed says, that data center projects are increasingly specifying the exclusive use of U.S.-made conduit. And as more projects aim for green-building benchmarks such as the U.S. Green Building Council’s LEED (Leadership in Energy and Environmental Design) certification, sourcing domestic-made conduit is another step toward realizing those sustainable ambitions.

4. Compliance Confidence

All conduit sold in the U.S. must meet specific compliance thresholds for safety and performance, including earning the seal of safety company UL Solutions. But the global manufacturing environment is so massive that it’s much easier for non-compliant, foreign-made products to slip through the compliance cracks.

American-made conduit is subject to frequent audits and advanced testing of key elements such as the application of zinc coatings. This testing is critical to addressing quality issues that could lead to product failure or poor performance months or years later.

5. Custom Conduit Solutions

Finally, when projects demand flexibility, custom solutions are key. More electrical contractors are embracing technologies like Building Information Modeling (BIM) software to create tailored solutions for complex projects.

This customized approach often requires different materials than those favored in traditional construction projects. For example, it places a premium on products such as EMT and conduit that’s manufactured in short lengths for easier transport. Zekelman has specialty conduit products such as 20’ EMT for easier transport, faster installation, and less waste, leading to efficiencies gains on both the job site as well as pre-fabrication shops, Reed says.

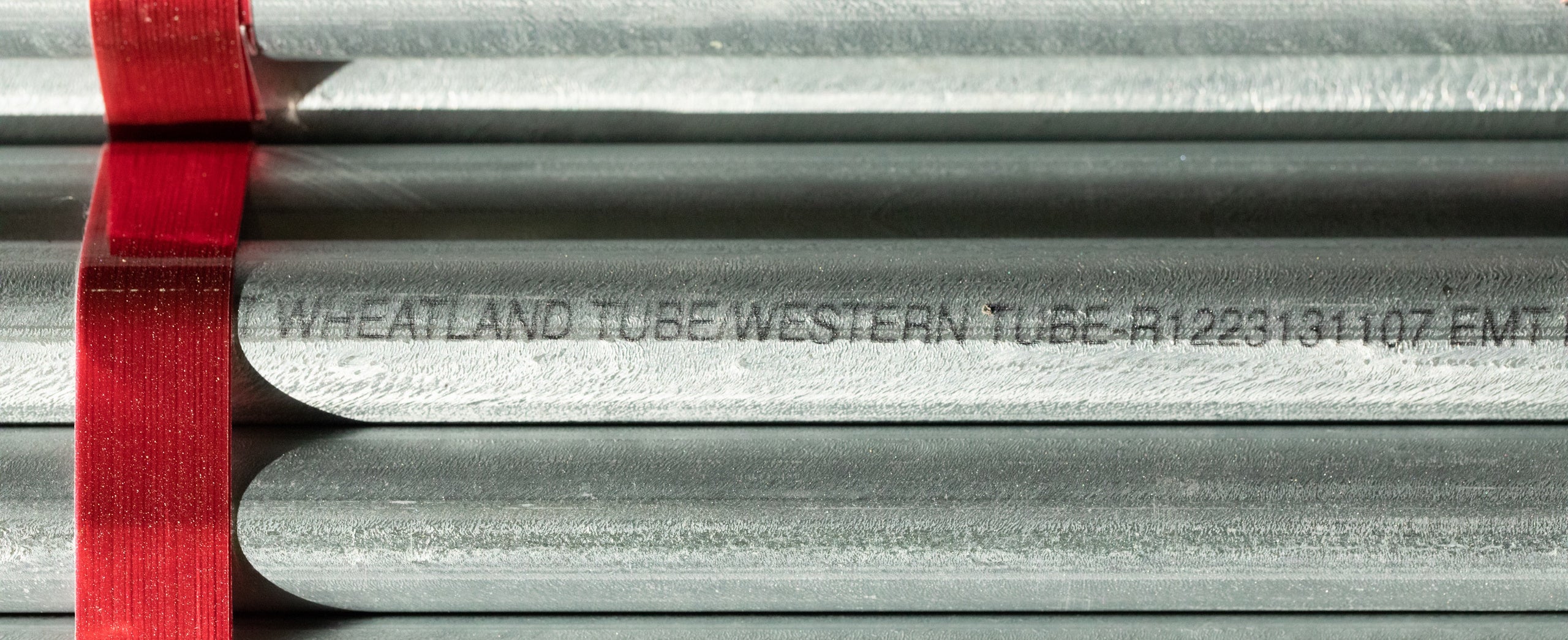

According to Reed, overseas competitors lag behind American manufacturers such as Wheatland Tube and Western Tube, companies of Zekelman Industries, when it comes to customized conduit solutions. Zekelman has been fast to identify and respond to demand for these emerging products. “It helps those operations become more efficient,” he says, “and that’s what prefab shops are all about.”

Take remodel jobs, which often come with unique challenges. For remodels where electrical contractors are attempting to work with walls that aren’t flush or piping that juts out in odd spaces, domestic manufacturers like Zekelman are able to provide custom fittings and elbows. These custom options enable contractors to complete their jobs seamlessly—despite the unique quirks of a building.

Superior quality may be the primary reason for choosing domestic conduit products, along with the economic boost that those purchases provide to American workers and communities. But when you consider these lesser-known advantages of buying U.S.-made conduit, the opportunities may surprise you—and even make you rethink imports for good.

There’s nothing better than building something you believe in.

Zekelman companies are in constant motion, expanding our teams and challenging convention.

"*" indicates required fields