DEMAND BETTER.

DEMAND DOMESTIC.

Domestic steel pipe and conduit are manufactured to meet all regulatory requirements and our own exacting quality standards. Demand domestic and be assured that every stick and elbow is ready to work harder for your project, your crew and your company’s reputation.

Learn about Zekelman’s recent legal action to combat imports.

When your reputation is on the line,

trust domestic quality.

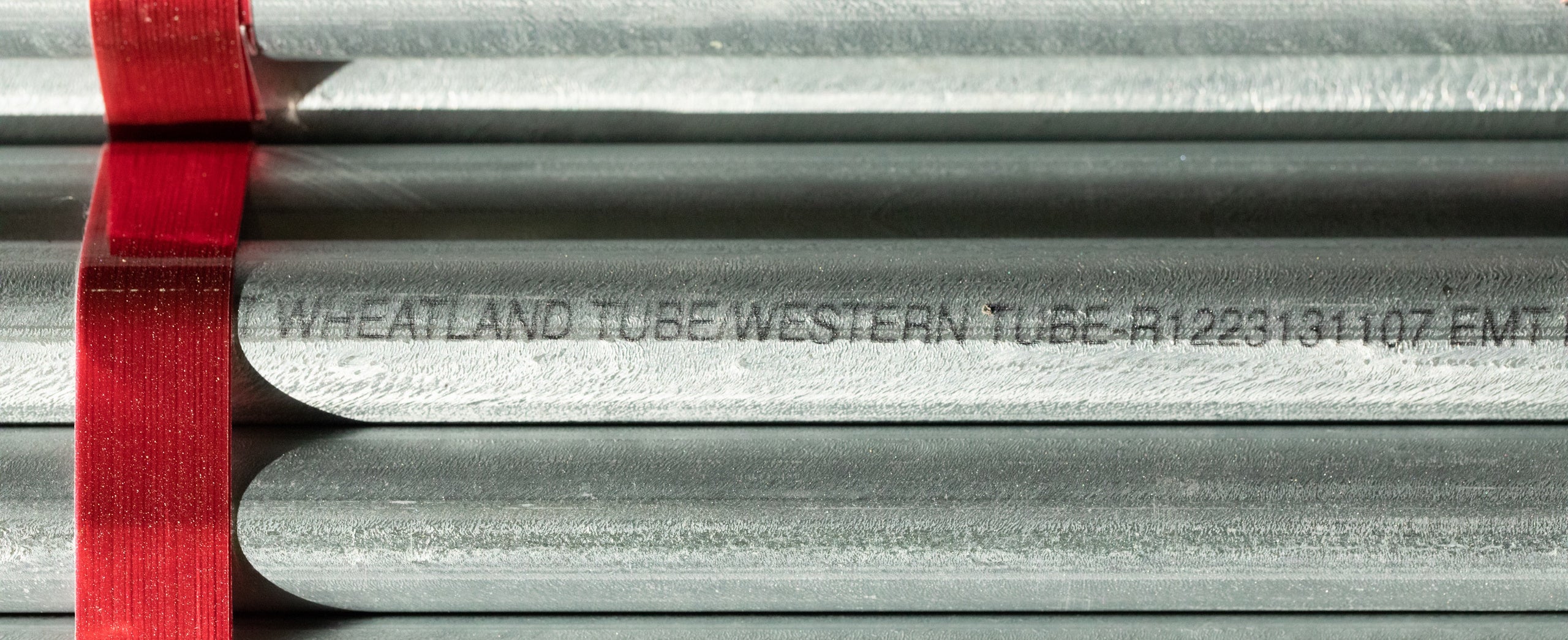

Too often poorly manufactured imported conduit underperforms on the job and needs to be tossed. Waste is expensive and frustrating for your crew. We know — we routinely test our own products against the imports. Demand conduit, EMT and EC&N from Wheatland Tube, Picoma and Western Tube and insist your strut be ZI-Strut. Be assured that every product is manufactured to the highest quality standards and Made in the USA.

More about domestic manufacturing

-

5 Lesser-Known Reasons to Demand Domestic Conduit

Beyond product quality, discover more reasons to choose U.S.-made conduit for your projects—and gain an edge imports can’t match.

-

How American Manufacturing Uplifts Communities and Builds Futures

For generations, local manufacturing facilities have fueled development and supported workers and families.

-

Engineered for Excellence: U.S.-Made Steel Conduit Sets the Standard for Safety and Performance

Rigorous manufacturing processes ensure that domestic conduit meets or exceeds industry standards, keeping contractors safe and compliant—an advantage often unmet by imported products.

Work with us.

Talk to us about your next project to see what domestic conduit can do for you.

"*" indicates required fields

Sign up to stay informed.

Zekelman champions domestic steel, and we want to work with you.

"*" indicates required fields